GREG MASICA — BASF TOTAL stressing safety, giving back to community through COVID-19

Published 12:30 am Wednesday, May 27, 2020

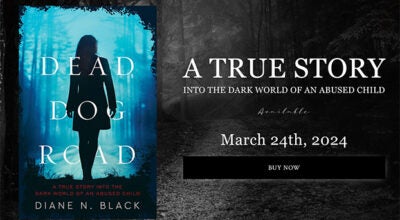

- BASF employees unload a truck of hand sanitizer for employees of the Medical Center of Southeast Texas in Port Arthur. (Courtesy photo)

|

Getting your Trinity Audio player ready...

|

As I write this message, our community is in the third month of living and working under exceptional circumstances as a result of the coronavirus (COVID-19) pandemic.

Life as we have known it has changed dramatically, and even our work life has been impacted.

Throughout this pandemic, the BASF TOTAL Petrochemicals facility in Port Arthur has continued to produce chemicals vital to the fight against the spread of COVID-19. The facility is a joint venture partnership between BASF and Total Petrochemicals & Refining USA.

Our facility is deemed critical infrastructure, and we’ve maintained manufacturing operations to supply two core products – ethylene and propylene.

These basic chemicals are used to make personal protective equipment (PPE — such as masks, gowns, face shields, goggles), hand sanitizers, foods, medicine and home and institutional cleaning and disinfection products, among others.

For example, our products are necessary for making protective screens that are being installed across grocery stores and customer-facing businesses as a protective measure.

To protect our employees and our communities, we enacted our pandemic plan in early March – before the State of Texas initiated stay-at-home orders. To minimize and limit exposure to COVID-19 and maintain safe operations, we are continuing the following safeguards at the site:

- Require employees to work from home if their job allows.

- Minimize the number of employees deemed essential at sites to keep operations running.

- Require employees to complete health questions and be tested for temperature before being allowed to come on site.

- Require the use of face coverings and gloves as appropriate.

- Direct employees to observe proper “social distancing” both generally and while on site.

- Increased cleaning and disinfection measures to be protective of employees.

As a result of our deliberate and swift actions and the attentive behaviors by all site team members to help limit transmission of the virus, our site has no recorded positive COVID-19 cases.

I’m extremely proud that our colleagues at BASF production sites in in New Jersey and Michigan have made more than 9,500 gallons of hand sanitizer for donation to health care facilities across the country.

Locally, we donated more than 150 gallons of hand sanitizer to the Medical Center of Southeast Texas, Baptist Hospital and the Southeast Texas Regional Emergency Operations Center.

Across the state, more than 900 gallons was donated to the Texas Department of Emergency Management for distribution to first responders and healthcare facilities and in communities near BASF sites in Texas.

The company also donated $365,000 to Feeding America, the nation’s largest domestic hunger-relief organization. Of that amount, $10,000 went to the Southeast Texas Food Bank to help our local communities.

BASF TOTAL Petrochemicals and the entire chemical industry sector are playing an important role during these difficult times.

As we face this the COVID-19 challenge together, I’d like you to know we are working hard every day to support our customers who in turn provide critical supplies to consumers. We are doing this while maintaining the highest levels of safety.

Greg Masica is VP and Site Manager of BASF TOTAL Petrochemicals. For more information, email carol.hebert@basf.com.